INSTANT

cut to size prices

cut to size prices

on all mainland UK orders

customer service

Click to find out more

Showing all 12 results

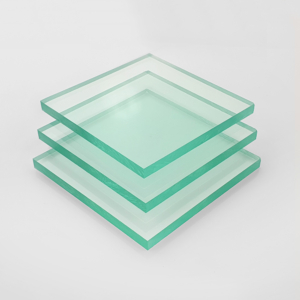

At Cut Plastic Sheeting we have several different clear plastic sheets available which are suited to different applications; from clear extruded Perspex® acrylic for use as replacement greenhouse panels to green edge ‘glass effect’ acrylic for use in retail displays or as safe and hygienic splashback. We even have several high-performance clear plastic sheets available for use in the most demanding environments such as clear polycarbonate for creating high-impact screens in sports arenas and PETG for use as machine guards in factories.

We stock a range of clear-cut to size plastic materials which have slightly different qualities making them suitable for different applications.

We have the knowledge, experience and technology to offer a bespoke design and fabrication service for plastic sheets to cater for almost any idea you can think of. Our team are happy to provide you with a free and no-obligation quote.

Contact us at 01752 917434 or via the “Bespoke & Trade Tab” on all product pages.

Clear acrylic sheet plastic is a superb alternative to glass in several applications in the home and commercial environment.

Acrylic sheet plastic can exceed the performance of glass in many areas including:

Clear acrylic is also known by the trade names, Perspex®, Lucite, Altuglas and Plexiglass. People also refer to plastic as Polyvinyl Chloride(PVC) or PVC sheets and Acrylonitrile Butadiene Styrene(ABS) or ABS Plastic.

All of our clear acrylics are remarkably resistant to damage and highly durable, caused by UV light, and they will not cloud, yellow or discolour in either indoor or outdoor applications. Furthermore, it has a low moisture absorption rate which ensures the sheet will not warp with repeated contact with water, making it able to withstand repeated cleaning and approved for food contact.

A clear acrylic sheet is also used where a superior aesthetic is required, and our non-reflective acrylic is perfect for use in gallery and exhibition spaces as a lightweight and high-strength alternative to picture glass.

Our cheapest type of clear plastic sheet is, Clear Perspex® Acrylic Sheet, from £48.48 per meter squared**.

**We work hard to get the best prices for all our customers, prices may change due to supplier and manufacturing costs.

We can measure all our plastic sheets in, Millimetres(MM, Mil), Centimetres(CM), Meters(M) and Inches. Both the width and height of a sheet can be tailored to your needs and applications.