Measuring rounded corners on sheet material can be difficult at first and the thought of it might be daunting, especially when precision and accuracy are key. Any small deviation or error in measurement can result in inaccurate or inconsistent results. That is why we have come up with a quick help guide to show you how is best to measure for a rounded corner.

How To Measure Rounded Corners?

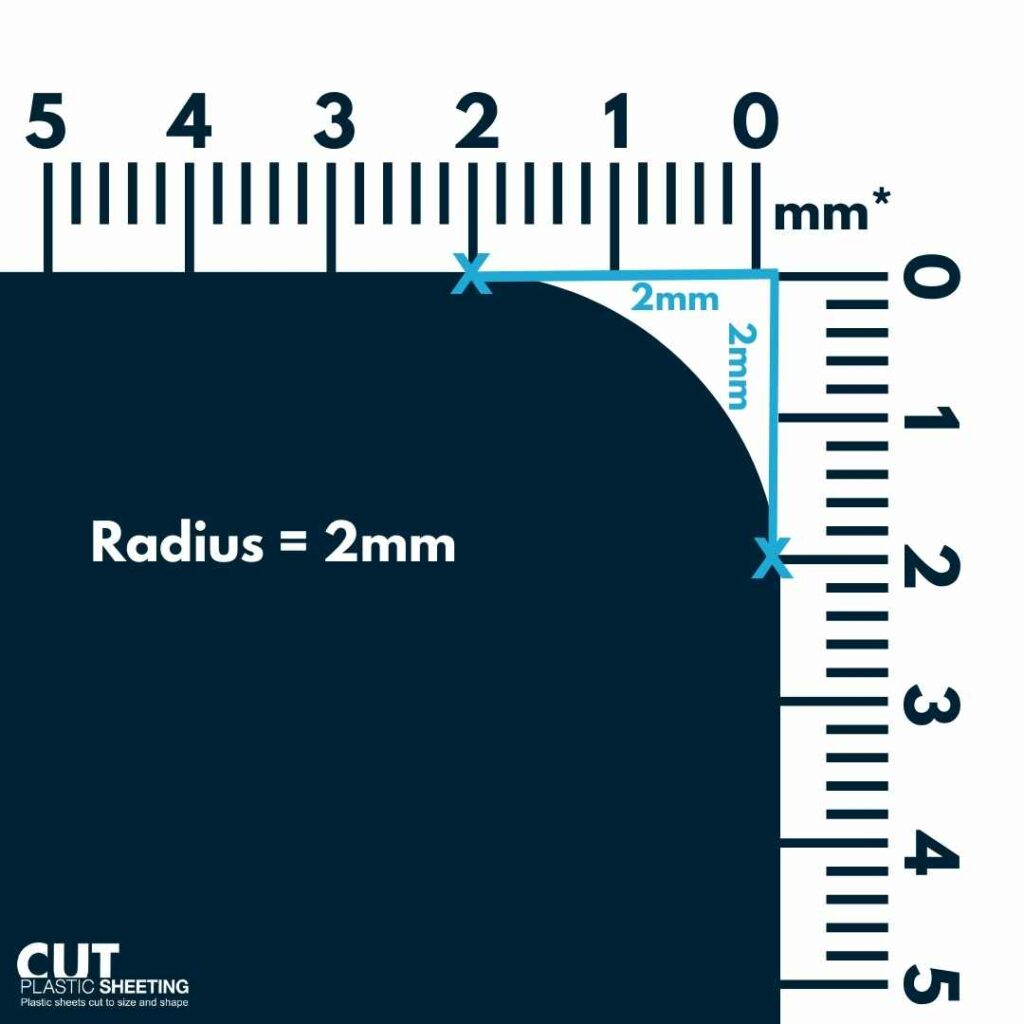

Measuring a rounded corner can actually be very straightforward with the right guidance and tools. All you really need is a framing square, or a couple of rulers, and a pencil! Take a look at our step-by-step guide below:

1. Place your framing square or ruler against the two edges

2. Find the point where the straight-edged line starts to curve

3. Measure from the point where the curve begins, to the end of the sheet

4. The distance from where to curve starts to the edge of the sheet should be the same on both sides.

5. The figure you get is your radius

If you need further advice, look at this helpful YouTube video.

Why Sheet Material Need Rounded Corners?

Firstly, rounded corners can enhance the aesthetic appeal of the material. Sharp corners can create a harsh and rigid appearance, while rounded corners can add a softer and more inviting feel. Rounded corners can also give the material a more modern and sophisticated look, which can be especially useful for marketing and branding purposes.

In addition to aesthetics, rounded corners can also improve the functionality of sheet materials. Sharp corners can easily get damaged or cause injury if they come into contact with people or other objects. By rounding the corners, the material becomes safer and less likely to cause harm or damage. Rounded corners can also reduce wear and tear on the material itself, making it more durable and long-lasting.

Comparison: Rounded vs. Sharp Corners

The debate between rounded and sharp corners in design and manufacturing is longstanding. Whether in architecture, product design, or digital interfaces like Clear Acrylic Perspex, the decision between these two corner types can significantly affect both functionality and aesthetics. Let’s delve into a comparative analysis:

Rounded Corners

Advantages:

- Safety: Rounded corners reduce the risk of injury, especially in high-traffic areas or where children are present. They can prevent cuts, bruises, and other accidental injuries.

- Aesthetics: They offer a softer, more approachable look. This can make designs such as Acrylic Sheets seem friendlier and more inviting.

- Durability: Rounded edges can resist chipping and wear better than sharp ones, making materials like Dibond Aluminium Composite Sheets longer-lasting.

- Ergonomics: Devices with rounded corners are more comfortable to hold for extended periods.

Disadvantages:

- Space Utilisation: Rounded corners might result in a slight loss of usable space.

- Manufacturing Complexity: Achieving a consistent, smooth curve can be more challenging, potentially increasing manufacturing costs.

Sharp Corners

Advantages:

- Precision: Sharp corners, as seen in modern designs of Clear Acrylic Perspex, exude a sense of precision and modernity.

- Space Efficiency: They can maximise the utilisation of space, especially in storage solutions.

- Simplicity in Manufacturing: Straight edges can be more cost-effective to produce.

Disadvantages:

- Safety Concerns: They pose a higher risk of causing injuries.

- Wear and Tear: Sharp edges, even on durable materials like Dibond Aluminium Composite Sheets, can be more susceptible to wear.

The decision between rounded and sharp corners should be guided by the specific requirements of the project and the intended use of the product or structure. While aesthetics play a crucial role, considerations around safety, usability, and durability are equally paramount.

For more information on Acrylic, Perspex, MDF, Dibond and Polycarbonate please visit our Guide and Blog sections of the website.

Cut Plastic Sheeting are based on the south Coast in Ivybridge, Devon UK. We have a full manufacturing facility which enables us to offer Cut To Size Acrylic as well as Cut To Size MDF. Shop our full range of products, including our Clear Acrylic, coloured acrylic and more recent MDF Wood Sheet ranges.

Our Team are always here to help with any enquiry, please send us an email or for more urgent needs give us a call – Contact Us