Mirrors are objects that are used in everyday life, all around us! Whether that’s in your home, gym studio, or at an art gallery, these pieces of reflective sheets have both practical and aesthetic benefits. Typically, mirrors are made from glass but sometimes they’re not always the best to use in every situation. In this blog, we will look into the popular alternative to glass mirrors which is using acrylic mirrors.

What Is Mirrored Acrylic and How Is Mirrored Acrylic Made?

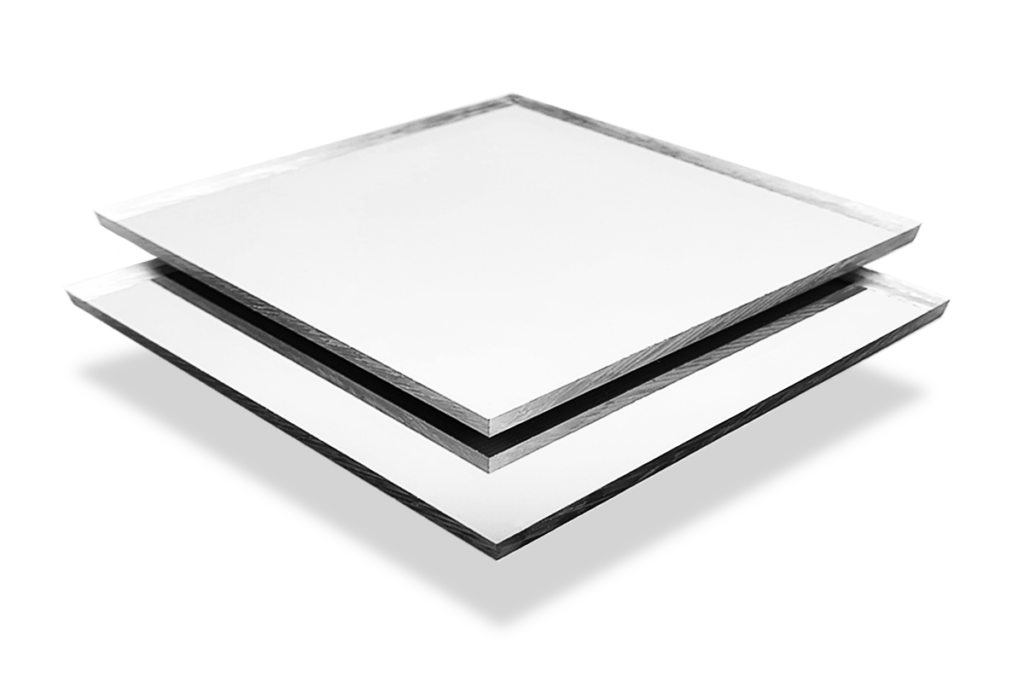

An acrylic mirror, also known as a plastic mirror or a plexiglass mirror, is a type of mirror made from acrylic plastic rather than traditional glass. Acrylic mirrors are created by applying a metal coating onto a cleaned acrylic sheet through a process called vacuum deposition. In a vacuum chamber, a small amount of metal, typically aluminum, is heated until it vaporises. The metal vapor condenses on the surface of the acrylic sheet, forming a reflective coating. To protect the coating, a transparent protective layer is often added. The mirrored acrylic sheet is then inspected, cut, shaped, and polished to the desired size and finish.

What Are The Benefits of Mirrored Acrylic?

Mirrored acrylic offers several benefits compared to traditional glass mirrors. Here are some of its advantages:

- Lightweight: Mirrored acrylic is significantly lighter than glass mirrors, making it easier to handle, transport, and install. This lightweight characteristic is particularly beneficial when using large mirror panels or incorporating mirrors into structures that require reduced weight.

- Shatter-Resistant: Acrylic mirrors are much more durable and resistant to shattering than glass mirrors. In the event of an accidental impact or mishap, acrylic mirrors are less likely to break into sharp, hazardous shards. This property enhances safety, particularly in environments where breakage could pose a risk, such as homes with children or public spaces.

- Flexibility: Acrylic is a highly flexible material, allowing for more versatile applications. It can be easily shaped, bent, or molded into various forms, making it suitable for curved or unconventional mirror designs. This flexibility expands the range of creative possibilities for designers and architects.

- Weather Resistance: Acrylic mirrors have excellent resistance to weathering and UV radiation. They are less prone to discoloration, yellowing, or deterioration when exposed to sunlight or outdoor conditions over time. This characteristic makes them suitable for both indoor and outdoor applications.

- Cost-Effective: Acrylic mirrors are generally more affordable than glass mirrors, making them a cost-effective alternative. The production process for acrylic mirrors is often less expensive, and their lightweight nature can also result in lower shipping and installation costs.

These benefits collectively make mirrored acrylic a popular choice in a wide range of applications, including interior design, architecture, retail displays, safety mirrors, point-of-sale signage, and decorative purposes.

What Are The Disadvantages of Mirrored Acrylic?

While mirrored acrylic offers several advantages, it also has a few disadvantages compared to glass mirrors. Here are some of the limitations to consider:

- Scratches: Acrylic mirrors are more prone to scratching than glass mirrors. The surface of acrylic is softer and more susceptible to abrasion, which can result in visible scratches over time, especially with improper cleaning or handling. Special care must be taken when cleaning acrylic mirrors to avoid scratching the surface.

- Lower Reflectivity: Although mirrored acrylic provides satisfactory reflectivity, it may not match the exact clarity and reflectivity of glass mirrors. The reflective coating on acrylic mirrors may not be as flawless or sharp, which can slightly diminish the overall clarity of the reflected image.

- Potential Distortion: Acrylic mirrors can exhibit slight distortions or warping, particularly in larger sizes or thinner sheets. This distortion is more noticeable when viewing the mirror from certain angles. While it might not be a significant concern for most applications, it’s important to consider the potential for distortion when selecting and positioning acrylic mirrors.

- Cleaning Challenges: Cleaning acrylic mirrors requires special care to avoid scratching or damaging the surface. Certain cleaning agents, such as those containing ammonia or abrasive particles, can cause harm to the mirror’s coating. It is recommended to use mild, non-abrasive cleaners specifically designed for acrylic surfaces to maintain the mirror’s appearance and longevity.

Despite these limitations, mirrored acrylic remains a popular choice for many applications due to its affordability, durability, and versatility. By considering these disadvantages and taking proper precautions, the potential drawbacks of mirrored acrylic can be mitigated, ensuring optimal performance and longevity.

What Can You Use Mirrored Acrylic For?

Mirrored acrylic has a wide range of applications across various industries due to its unique properties. Its versatility, lightweight nature, and shatter resistance make it a preferred choice for numerous industries seeking reflective surfaces that offer durability, safety, and design flexibility. Here are some common uses for mirrored acrylic:

Signage and Displays

Mirrored acrylic is popular for signage, retail displays, and exhibition booths. It can be cut into custom shapes, engraved, or used as a reflective backdrop to enhance visual appeal and draw attention.

Home Decor Applications

You can incorporate acrylic mirrors in various ways to enhance the style and functionality of your living spaces. They work well as wall mirrors, splashbacks, garden mirrors and wardrobe mirrors.

Architectural Applications

Mirrored acrylic finds its place in architectural designs, both indoors and outdoors. It can be used for decorative elements, cladding, room dividers, and unique architectural features, providing a reflective and modern aesthetic.

Shop Interior Designs

Mirrored acrylic is used in retail environments to create eye-catching displays and highlight specific products. It can be integrated into shelving, countertop displays, and product stands to enhance visual appeal and create an attractive shopping experience.

Acrylic Mirror FAQ's

Attaching an acrylic mirror depends on the specific installation requirements and the surface to which it needs to be attached. Here are a few common methods for attaching an acrylic mirror:

Adhesive: One of the simplest ways to attach an acrylic mirror is by using an adhesive specifically designed for mirrors or acrylic surfaces. Ensure that the adhesive is suitable for use with acrylic materials and follow the manufacturer’s instructions. Apply the adhesive to the back of the mirror in a grid pattern or as recommended, and then press it firmly onto the desired surface. Use tape or clamps to hold the mirror in place until the adhesive cures.

Double-Sided Tape: Double-sided adhesive tape can be an effective and easy method to attach smaller acrylic mirrors to a smooth, clean surface. Cut the tape into appropriate lengths or strips, and apply them to the back of the mirror. Then, carefully position the mirror on the desired surface and press it firmly to ensure a secure bond.

Frame or Molding: Another option is to frame the acrylic mirror or use molding around its edges. This method not only provides a decorative element but also helps secure the mirror. The frame or molding can be attached to the wall or surface using appropriate hardware, and the mirror is then mounted within the frame or held in place by the molding.

It’s important to ensure that the surface where the mirror will be attached is clean, dry, and free from any dirt, grease, or dust particles. Additionally, always follow the manufacturer’s instructions and guidelines specific to the adhesive or mounting hardware you choose to ensure proper installation and a secure attachment.

Acrylic mirrors are more prone to scratching than glass mirrors. The surface of acrylic is softer and more susceptible to abrasion, which can result in visible scratches over time, especially with improper cleaning or handling. Special care must be taken when cleaning acrylic mirrors to avoid scratching the surface.

If you are unable to use Acrylic Mirrors and do not want to use Glass, another option to use is Mirrored Polycarbonate. A tougher alternative to acrylic – polycarbonate mirrors are extremely strong but still lightweight.

Mirrored Sheets Cut To Size

At Cut Plastic Sheeting, we offer various types and colours of mirrored sheeting. Whether you want a coloured acrylic mirror sheet for fun interior design projects or a large mirrored sheet for an outdoor statement piece, we have cut to size mirrored sheets available.

For more information on Acrylic, Perspex, MDF, Dibond and Polycarbonate please visit our Guide and Blog sections of the website.

Cut Plastic Sheeting are based on the south Coast in Ivybridge, Devon UK. We have a full manufacturing facility which enables us to offer Cut To Size Acrylic as well as Cut To Size MDF. Shop our full range of products, including our Clear Acrylic, coloured acrylic and more recent MDF Wood Sheet ranges.

Our Team are always here to help with any enquiry, please send us an email or for more urgent needs give us a call – Contact Us