Description

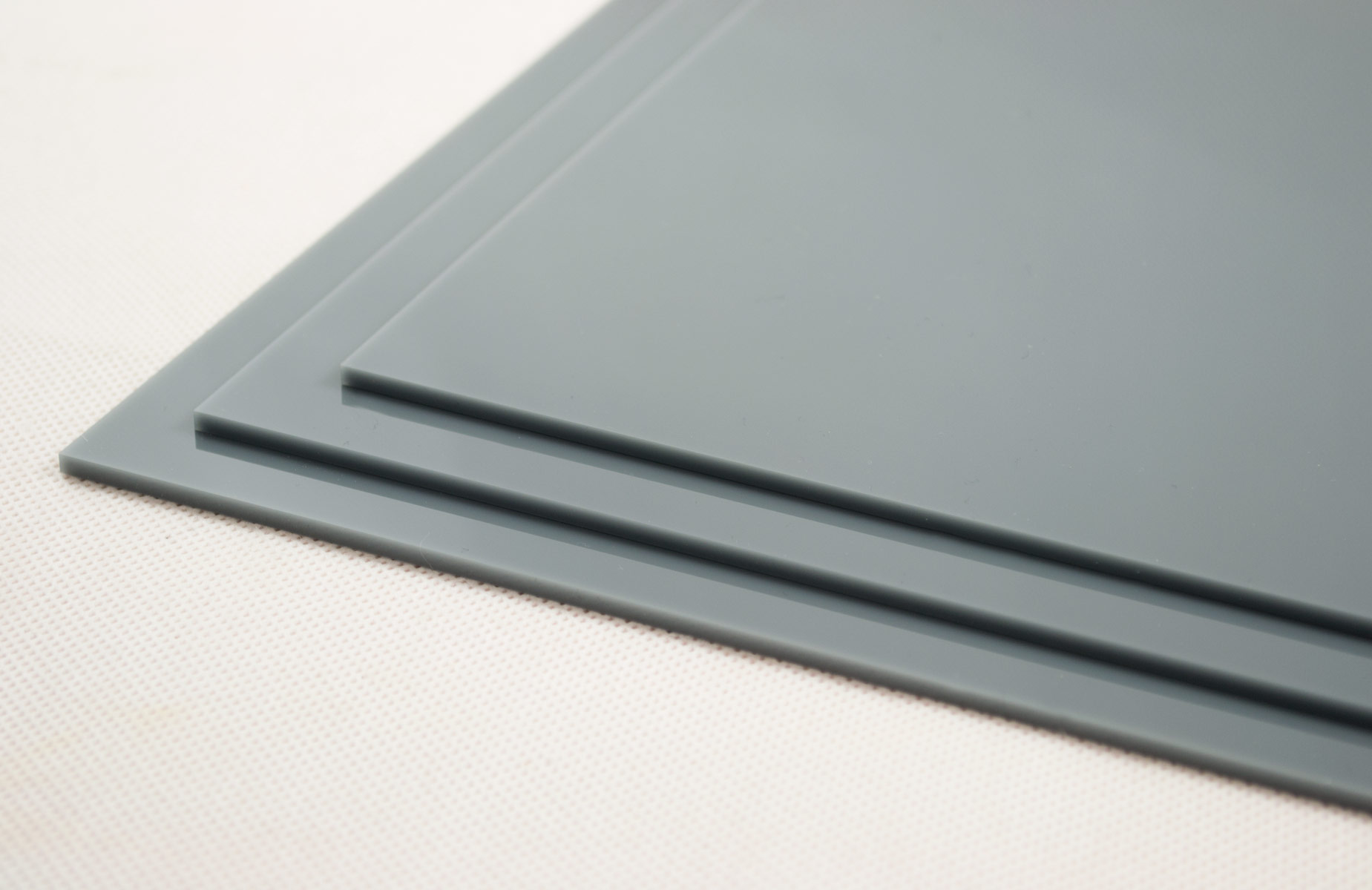

Grey Acrylic

Discover the exceptional versatility of our premium Neutral Grey Cast Acrylic Sheets. Designed to meet the demands of both commercial and DIY applications, this material offers unmatched durability and aesthetic appeal. Whether you’re fabricating retail displays, architectural installations, or even small home decor projects, our grey acrylic sheeting provides the strength and flexibility you need.

Made from a high-grade acrylic material that’s both lightweight and UV-resistant, this sheeting is suitable for indoor and outdoor applications. It maintains its sleek, grey colour without yellowing over time, making it a reliable choice for long-term projects. Its machinable qualities mean it can be easily cut, drilled, and formed to fit your specifications.

Ideal for a broad range of applications, including signage, architectural elements, and point-of-sale displays, this grey acrylic also lends itself to smaller-scale DIY endeavours, from custom picture frames to model building. Available in various thicknesses and sheet sizes, you can customise the material to suit your project’s unique requirements.

Experience the blend of utility and elegance our Neutral Grey Cast Acrylic Sheets offer. Order today to unlock endless possibilities for your next project.

Properties of our Grey Acrylic Sheets:

- Neutral grey colour

- Can be cut, drilled, routed and bent using common tools

- Ten times stronger than glass and less than half the weight

- Resistant to water, chemicals, UV light, and salt spray

- Ideal for use in kitchens and bathrooms as a Grey Acrylic Splashback (Please see details)

- Food safe

- Fully recyclable

- Easy to clean and maintain

- Unaffected by sun or salt spray

- Excellent surface hardness and durability

- Superb chemical resistance – better than most plastics

- Temperature range of -30 to 160° F for continuous service

- Sheet manufacturing process: Cast

- Supplied with protective film on both sides

- Hygienic and easy to clean, colour will not fade over time

- Low levels of light transmission may occur, which is normal for this material.

Important Notes

- To get an accurate representation of the colour, please order a sample as the colour of sheets may differ slightly due to variances in your computer display

- We recommend all acrylic sheets are not installed closer than 200mm to an open heat source such as a gas/electric hob.

- Due to the manufacturing process of cast acrylic, the thickness of the sheet has a maximum tolerance of +/-10%.