Polycarbonate (PC) is our strongest clear sheet material and is incredibly popular due to its features and functionality. It can be used for many applications in both residential and commercial settings. As it is such a versatile material, we thought it would be helpful to answer the most frequently asked questions we get about our Polycarbonate Sheet.

Key Features & Benefits:

- It is weather-resistant so can be used for external use

- As it is half the weight of glass it is easy to handle

- Great thermal stability and safe to use with foods

- Clear Polycarbonate has a maximum light transmission of up to 90%

- The biggest advantage would be its incredible strength and ability to withstand breakages. Compared to glass, Polycarbonate is over 200 times stronger

What are the different variations of Polycarbonate?

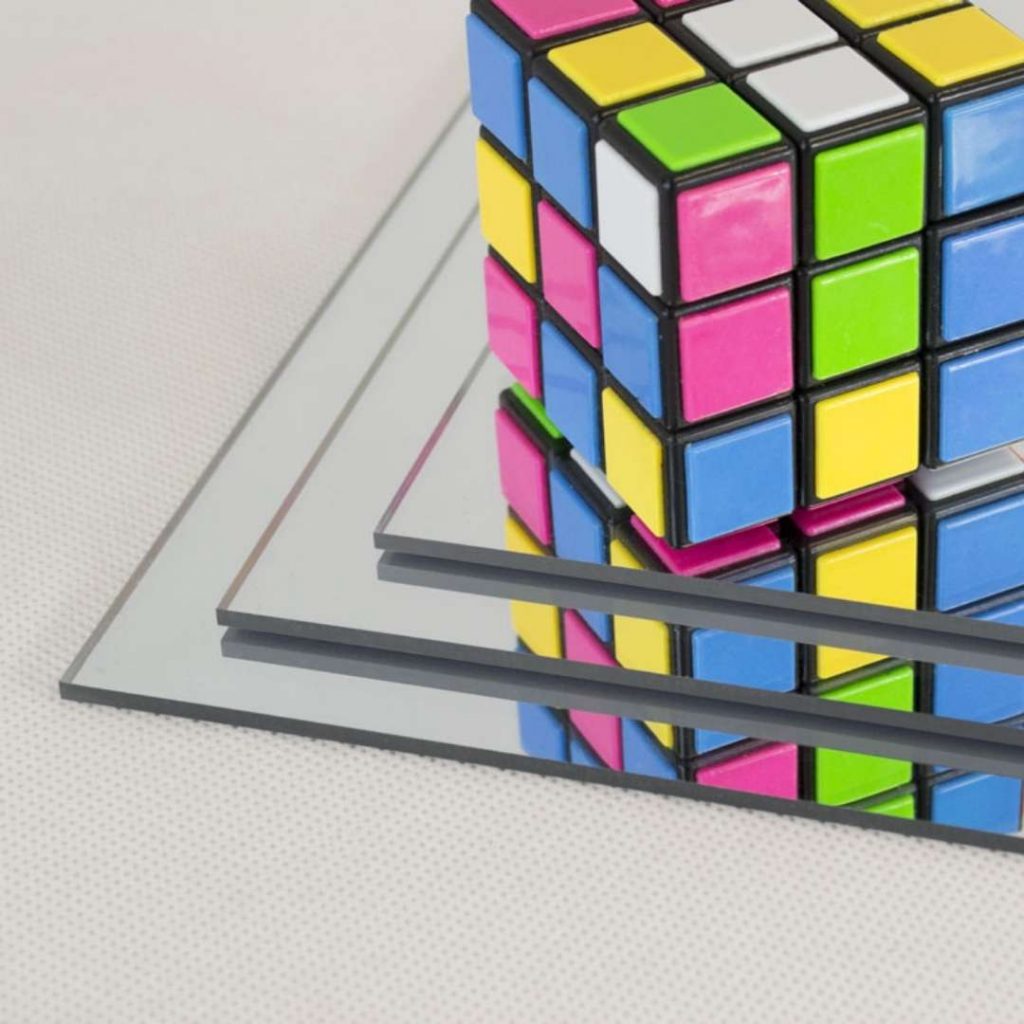

Our standard clear sheet of Polycarbonate comes in thicknesses between 2mm – 10mm. It also has a maximum sheet size of 3000mm x 2050mm that can be cut to any shape and size. As well as the standard sheet, we also offer different variations which may be more suitable for your project:

- Mirror: An alternative to glass mirrors and a tougher alternative to acrylic; polycarbonate mirrors have remarkably high impact resistance

- Scratch Resistant: Has all the great features of standard Polycarbonate but with a durable coating on both sides to reduce the chance of scratches and scuff marks

- Anti-Reflective: Perfect if you are in need of both incredible strength and reduced unwanted glare and reflections

Popular Uses

There are endless uses for Polycarbonate which is why it is so popular! It can be used for both business and residential use and can be used in internal and external applications. If you are looking for an at-home DIY project some common applications are greenhouse panel replacements, shed windows, frames and tabletop replacements! Or if you are looking for more large scale business uses, Polycarbonate can be used for skylights in buildings, vending machines and even bulletproof windows!

Is Polycarbonate recyclable?

Yes, Polycarbonate gets turned into a granulate which then gets re-manufactured.

What are some disadvantages?

- Because of the chemical structure of polycarbonate, the only option is clear or mirrored so it lacks colour options

- Due to its incredible features and strength, Polycarbonate can be an expensive material

- Over time, it will adopt a yellow hue with prolonged exposure to the UV rays

- You cannot polish the edges of Polycarbonate

How does polycarbonate compare to glass or acrylic?

Polycarbonate is more impact-resistant than glass and has similar optical clarity. It is lighter than glass and less likely to shatter. Compared to acrylic, it is generally more impact-resistant but may scratch more easily.

Is polycarbonate suitable for outdoor use?

Yes, polycarbonate is often used outdoors because it is UV-resistant and can withstand weather conditions. It’s commonly used for applications like outdoor signage and greenhouse panels.

Does polycarbonate yellow or degrade over time?

Polycarbonate is UV-resistant, but it can still undergo yellowing or degradation over an extended period of time when exposed to harsh UV radiation. Using UV-resistant coatings can help mitigate this.

Get in touch!

Our Polycarbonate sheets are available to cut to custom size and shape and come in all different types of thicknesses. If you have any questions that have not been answered here or want to discuss an upcoming project – please get in touch with our sales team.